| TECHNICAL DATA |

| |

| CONTRLLER: |

| PLC control |

| Multi Language Selection |

| |

| DISPLAY: |

| Colour touch panel 8” |

| Continuous read out of operation details |

| 1 production screen with all data+keyboard |

| |

| PROGRAMS: |

| 999 Programs: |

| Autoduction calculation of pitch,layer full ,layer spread |

| |

| PROGRAMMING: |

| User friendly graphic for easy understanding |

| 1 programming screen enables set up in very short time |

| |

| DATA MEMORY : |

| Interface for software updates |

| USB slot |

| |

| OPERATOR CONTROLS: |

| Control Board Function/Save/Teach keys |

| Hand Control Unit:Joystick,start/stop knob |

| Foot Pedals:speed control,spindle brabe,creep |

| |

| SETTING OF LEFT AND RIGHT LIMITS: |

| With teach system |

| |

| SPEED AND TORQUE CHANGE: |

| 2 Pulleys |

| One with high torque for larger wires |

| One with high speed for light wires. |

| |

| TRAVERSE: |

| Precision ball screw |

| Servo Motor 0.4kw |

| |

| MOTOR POWER: |

| Servo Motor 0.4kw |

| |

| MACHINE WEIGHT: |

| Approx.30 kg net,50 kg gross |

| |

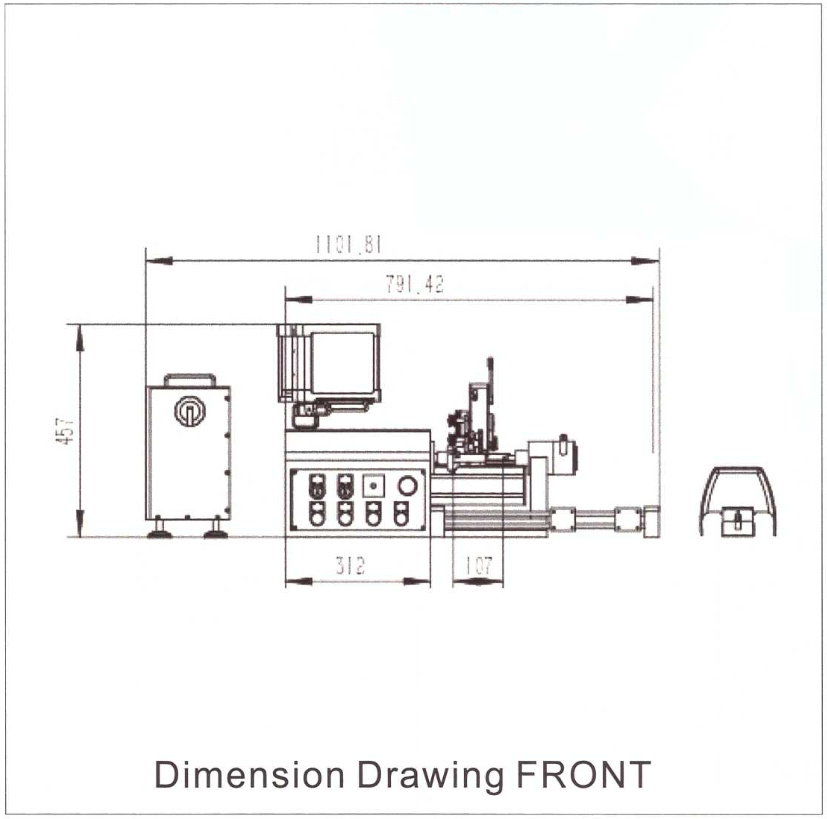

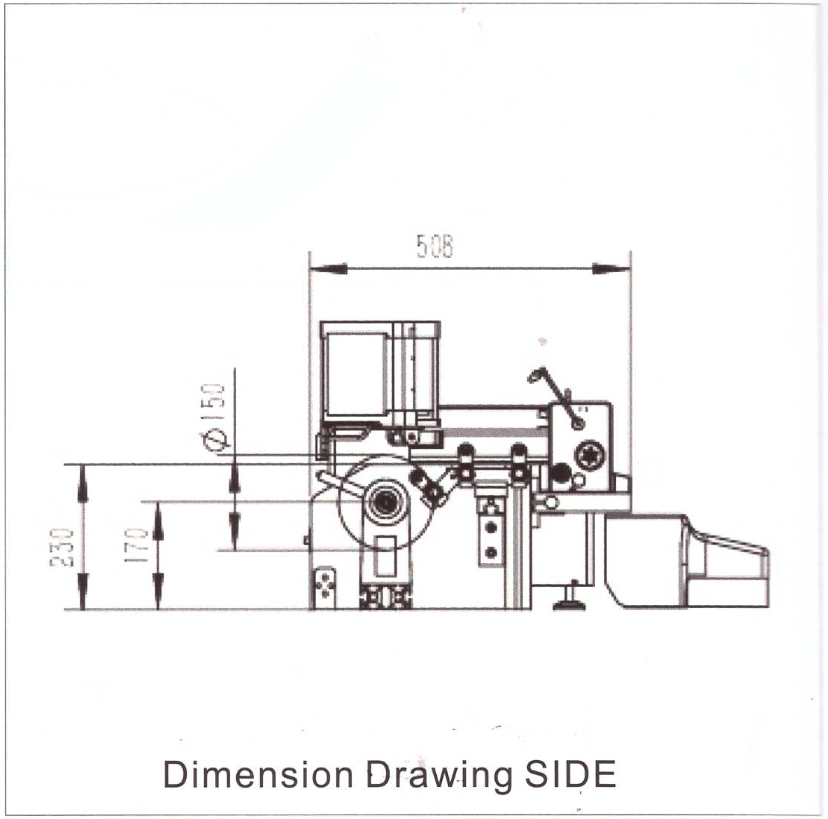

| MACHINE SPACE: |

| Approx.500 mm x 500 mm |

| |

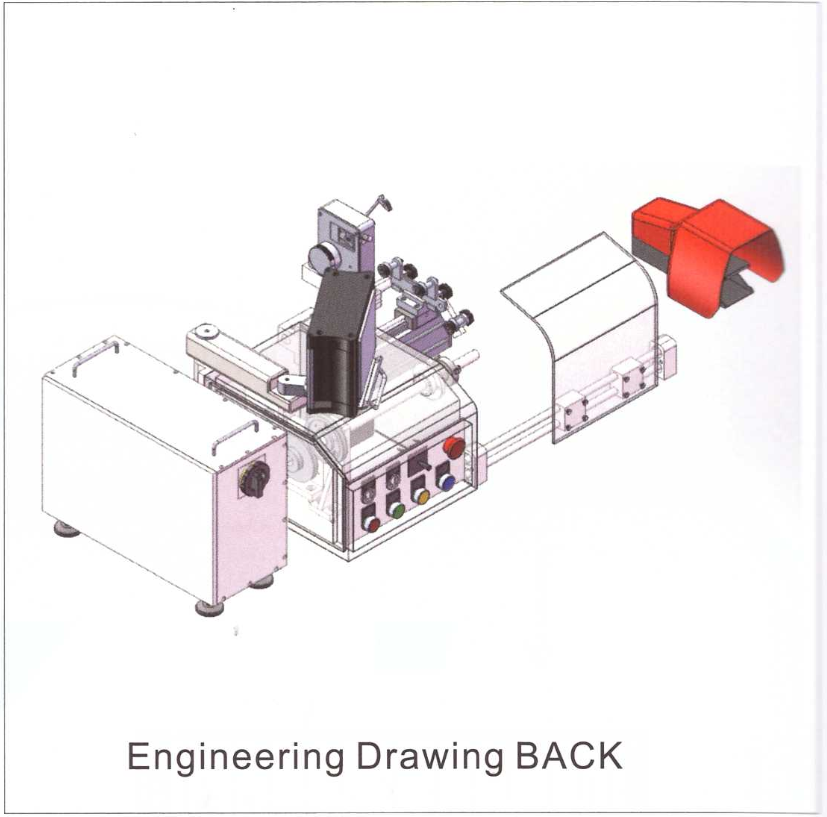

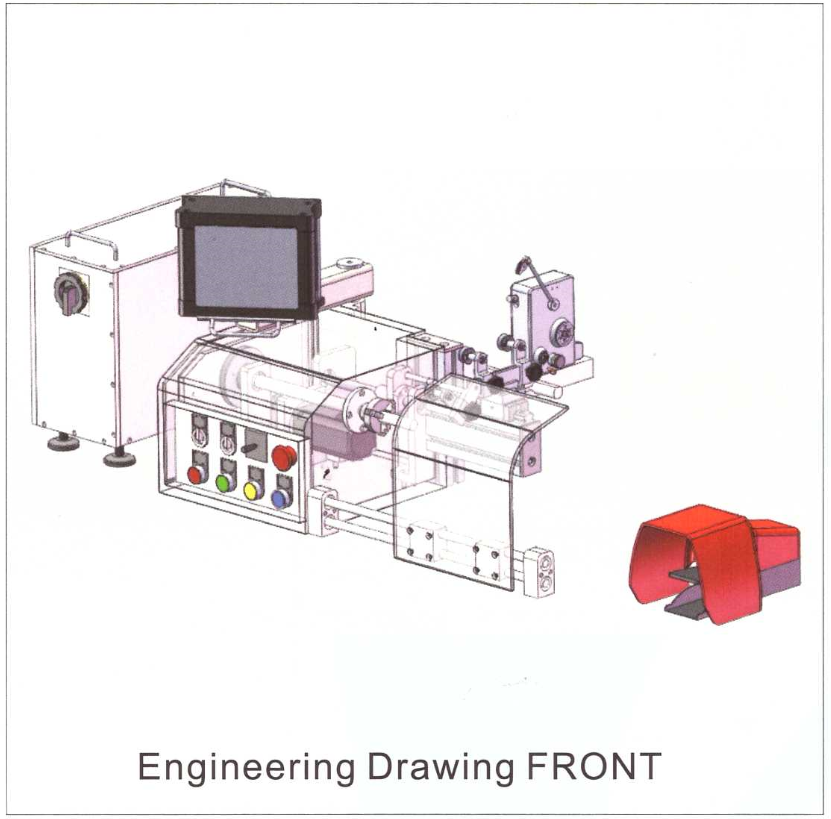

| BASIC MACHINE CONSISTS OF: |

| 1x headstock,iron casting |

| 1x winding spindle with facelate |

| 1x traverse unit |

| 1x wrie guide arm |

| 1x safety protective cover |

| 1x touch panel |

| 1x control unit |

| 1x foot pedal(speed control and spindle break) |