VC220-TPB |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

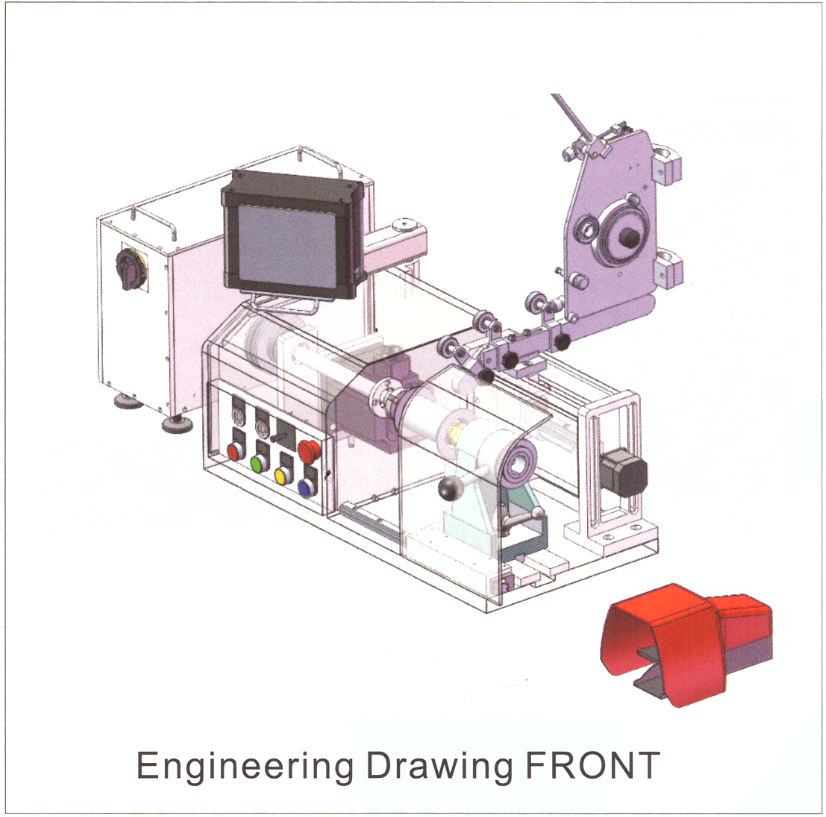

| The VC220-TPB is a Hi-Tech bench machine with PLC control and incorporates VC's flexible system with interchangeable wire guides and tensioners.It is designed for hi-end applications and built SERVO motors for head drive and core drive. The software guides the operator through the porgramming with clear 220-TPB extremely fast to set up and very easy to use. Typical applications for the bench machine VC 220-TPB are the production of small coils. It is made of high quality iron framework and robust mechanical parts.Two interchangeable motor pulleys are fitted as standard to give four ranges of torques and speeds. The wire guide carriage has been constructed using a precision ball screw and is mounted on a steel bar with linear bearing guides. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||